PROJECT SPOTLIGHT

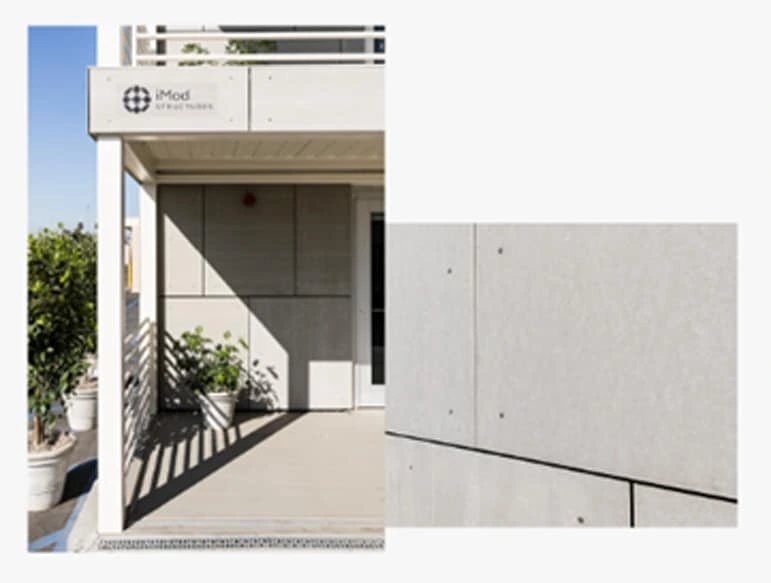

iMod Structures & DDC Journal Modular Feature

Modular construction company addresses need for greater flexibility, resiliency and long-term ROI in school facilities in California with high-performance modular classrooms

24 tons of steel

Building The Future

Future-proof buildings

THE CHALLENGE

As prefabricated modular construction continues to grow in response to fluctuating student enrollment, on-site challenges and nationwide labor shortages, iMod Structures (IMS) is changing the game in California. The company is transforming how school facilities are designed and built, using innovative modular and foundation design and rapid, high-volume manufacturing to create 21st century learning environments that are Future Proof.

Leveraging lessons learned by the Los Angeles Unified School District (LAUSD) over the past several decades, IMS aims to replace thousands of traditional wooden bungalows at K-12 schools, community colleges and universities throughout the state with high performance-modern classrooms based on a distinctive prefabricated modular building system. These new classrooms will dramatically enhance the learning environment for today’s students while giving school districts and university systems the flexibility needed to adapt to an uncertain future.

Compounding the issue are the locations of the trailers, which were installed to meet the demographics and student enrollments at specific schools 20 or 30 years ago. Things have changed radically since then. To keep up with the city’s constantly changing demographics and ever-evolving student needs, LAUSD recognizes the need for far greater flexibility, including the ability to relocate facilities and seamlessly adopt advancing technology and new digital teaching tools, to better accommodate change and strengthen the district’s future of education.

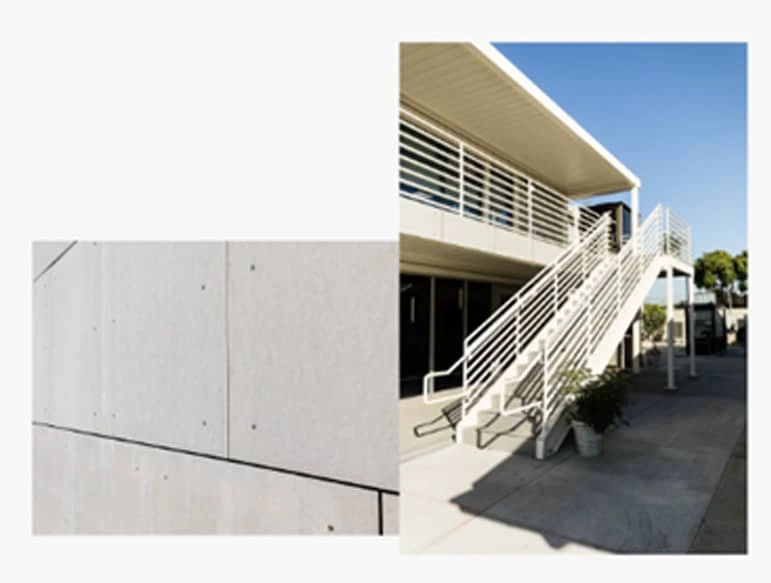

Initial schools taking advantage of the flexibility of the Future Proof characteristics of the iMod Structures high performance classrooms are the California State University Maritime Academy in Vallejo, Calif., Gateway Charter School in Sacramento, and Mare Island Technology Academy, a charter middle and high school in Vallejo. iMod classrooms are scheduled to be installed at those campuses through this Summer and into the Fall.

During the 1980s and 1990s, LAUSD—the largest school district in California and the second largest in the country—was racing to keep pace with exceedingly high student enrollment. The district deployed 7,000 wooden trailers to provide additional learning spaces and balance student-teacher ratios. While this addressed Los Angeles’ educational system facilities needs at the time, the traditional wooden trailers are now well beyond their intended lifespans.

GROUNDBREAKING DESIGN

The iMod Structures building system

The iMod Structures building system is based on a moment frame design and features sustainable, energy efficient building materials that are not susceptible to mildew, mold and moisture damage commonly found in traditional modular classrooms. Each classroom comprises 24 tons of steel and can be moved and relocated as the landscape of a school district evolves. By rethinking the definition of permanence, a new type of longevity is born—fulfilling the first tenet of a future-proof building.

Future Proof

“To be truly future proof, you must be able to relocate the building,” says Craig Severance, a Principal with iMod Structures. “Our buildings are easily relocated and reconfigured, and we have a highly skilled and experienced team steeped in that practice. If you have one of our classrooms in a particular location and 5, 10 or 20 years later you need them across town at another campus within the school district, you simply disassemble, relocate, and reassemble them where they are needed. And it can be done within a few days, minimizing school downtown and disruption of our children’s education.”

Flexibility

Fully future-proof buildings must also have the flexibility not just to expand or shrink as the needs and goals of an organization change but to seamlessly accommodate advances in technology. To accommodate high performance flexibility at scale, iMod has developed a component strategy to classroom fabrication. “The future of construction is on the assembly line,” says Reed Walker, a Principal at iMod Structures. “We have partnered with multiple OEM suppliers that provide component or preassembled products similar to sub-assemblies in large scale manufacturing industries. One of our primary partners, DIRTT, prefabricates our interiors including framing, wall finishes and power using ICE, their proprietary design software. Schools have the ability to customize their learning environments and modify or change them in the future by simply ordering new products from DIRTT such as replacing a magnetized, whiteboard panel with a wall-sized interactive LCD or even add virtual reality and other immersive learning capabilities. We can easily accommodate ever changing classroom technology including advances in distance learning that we expect to happen in the coming year.”

US Geologic Survey

With a 99 percent chance that one or more 6.7 magnitude or greater earthquakes will hit California within the next 20 years, according to scientists at the US Geologic Survey, the building system must also be sustainable and resilient enough to withstand this projected seismic activity. Based on the Platinum Earthquake Rating by the US Resiliency Council, iMod Structures’ classrooms are expected to be open for school operations within days after the biggest predictable seismic events, with minimal damage. The IMS classrooms are the first and only educational facilities in the country to receive such a rating.

Recognizing early on that heating and cooling the modular buildings evenly presented challenges to ensure comfortable and ultra-quiet operations, IMS worked directly with an innovator and HVAC industry veteran Shawn Intagliata the founder of Cobalt Creed, Missouri-based heating, cooling, and air quality specialist. Cobalt Creed provided design and advanced, customized HVAC solutions for improved efficiency and comfort.

Shawn Intagliata and Cobalt Creed are disrupting the HVAC industry, “Delivering HVAC the way it should be, DIRECT from the factory”.

“Each of our classrooms comprises four modules – three are fully conditioned space, and the fourth is a roofed terrace deck which provides protection from the elements and a virtual sidewalk accessing classrooms in a single or a multi-story configuration. In those three conditioned space modules, the center one contains the entire HVAC system. There is no equipment on the roof or on the side of the building. That system is fully charged when it leaves our factory,” Walker says. “Just plug it in and walk away. It’s fully self-contained in that center module. It also is designed to evenly distribute air across the entire ceiling, and it’s extremely, extremely quiet operating in the low 40db range.”

BUILDING FOR THE FUTURE

In addition to designing and building relocatable, reconfigurable classrooms that can quickly address school districts’ rapidly changing needs, IMS is equally focused on creating a high-quality learning environment within each structure. By leveraging technology—the fifth and final tenant of the iMod Future Proof building system—IMS has again placed sustainability and adaptability at the forefront with modern 21st century classrooms that are ready to integrate and accommodate the digital learning tools of the future. IMS’ current focus remains on providing high performance classrooms and school facilities for K-12 schools, community colleges, four-year colleges and universities in California. However, once the company achieves scale in the Golden State, it plans on exploring select opportunities this specialized modular construction system could effectively address.

“We will expand and achieve scale,” says Severance. “And once we do, not only could we transport our product to different regions of the country, we could also diversify into other verticals—healthcare facilities, relief housing, housing from natural disasters like hurricanes or tornadoes or firestorms. We are not doing that now because we have, as a small business, a focus on one product, which are classrooms for the California market, but the future will allow us to diversify into other verticals.”